FRP Absorption Tower & Derived Facilities

A new type of waste gas purification device made of FRP, designed for efficient treatment of acidic and cyanide-containing waste gases.

Key Features

Product Overview

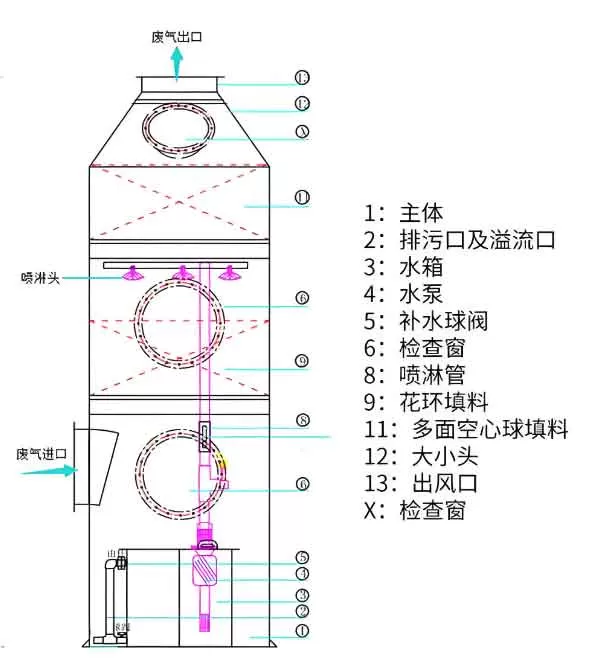

The FRP Absorption Tower is a new type of waste gas purification device primarily made of Fiberglass Reinforced Plastic (FRP). It features a circular overlapping segmented assembly structure, with an exterior anti-aging, flame-retardant polyester resin layer, giving it characteristics such as corrosion resistance, high strength, and light weight. It is mainly used for the treatment of acidic waste gases like nitric acid, sulfuric acid, chromic acid, and cyanide-containing waste gases, also possessing functions for gold and silver recovery.

Working Principle

Gas is fed into the FRP absorption tower by a fan, flowing from bottom to top. The absorption liquid is pumped to the top of the tower and uniformly sprayed downwards, creating a counter-current absorption. The neutralized gas passes through the demisting section and is then discharged into the atmosphere. Different acidic gases are absorbed by different absorption liquids, achieving high purification efficiencies (e.g., >98% for HCl mist, >97% for H₂SO₄ mist, >90% for HNO₃ mist, >95% for cyanide-containing waste gas).

Advantages

Applications

Technical Specifications

| Parameter | Value |

|---|---|

| Hydrochloric Acid Mist Purification Efficiency | >98% (with 2-6% NaOH solution) |

| Sulfuric Acid Mist Purification Efficiency | >97% (with 2-6% NaOH solution) |

| Nitric Acid Mist Purification Efficiency | >90% (with 2-6% NaOH solution) |

| Cyanide-containing Waste Gas Purification Efficiency | >95% (with NaClO solution) |

| Energy Saving (Circulating Pump) | 10-15% reduction in energy consumption |

| Material | FRP (Flame-retardant vinyl ester unsaturated resin, alkali-free glass fiber) |

FRP Manufacturing Process

FRP manufacturing is a technical system for producing composite materials that combine the hardness of glass with the toughness of steel. This material uses resin as the matrix and glass fiber as the reinforcing material, forming structural products through various molding methods. The main molding processes include hand lay-up, compression molding, filament winding, and pultrusion. Our company primarily uses two production processes:

2.1 Hand Lay-up Molding Principle

Hand lay-up molding, also known as contact molding, is the earliest and most widely used molding method in the production of resin matrix composites. It involves using a resin mixture with a curing agent as the matrix and glass fiber and its fabrics as reinforcing materials. These are manually laid up on a mold coated with a release agent, allowing them to bond together to create FRP products. The matrix resin typically uses unsaturated polyester resin or epoxy resin, and the reinforcing material usually uses alkali-free or medium-alkali glass fiber and its fabrics. Hand lay-up molding requires minimal mechanical equipment, making it suitable for multi-variety, small-batch production and unrestricted by product type or shape.

The process involves: first, applying a release agent to the cleaned or surface-treated mold forming surface, and after it is thoroughly dry, brushing a gel coat or resin mixture (with curing agent, accelerator, pigment paste, and other additives mixed evenly) onto the mold surface. Subsequently, cut glass cloth (mat) and other reinforcing materials are laid on top, ensuring thorough resin impregnation and removal of air bubbles. This layering operation is repeated until the design thickness is reached, followed by curing and demolding.

2.2 Filament Winding Molding Principle

Filament winding is one of the main manufacturing processes for resin matrix composites. It is a method where continuous fibers or fabric tapes are impregnated with resin adhesive and then continuously, uniformly, and regularly wound onto a core mold or liner using specialized winding equipment under controlled tension and predetermined patterns. The material is then cured in a specific temperature environment to form a composite product of a certain shape.

Molding Equipment

Fiber winding machines are the primary equipment for filament winding technology. The design and performance of fiber-wound products are realized through winding machines. According to control forms, winding machines can be divided into mechanical winding machines, digital control winding machines, microcomputer control winding machines, and computer numerical control winding machines, which represent the four stages of winding machine development. The most commonly used are mechanical and computer numerical control winding machines. A fiber winding machine typically consists of a machine body, a transmission system, and a control system. Auxiliary equipment includes impregnating devices, tension measurement and control systems, yarn racks, core mold heaters, pre-impregnated yarn heaters, and curing equipment.

Other FRP Derived Products

FRP carbon boxes, FRP sewage covers, FRP gratings, FRP pipes, FRP flanges, elbows, tees, etc.