High Voltage Electrostatic Precipitator

Efficiently removes dust and tar mist from industrial flue gas, ensuring environmental compliance and resource recovery.

Key Features

Product Description

The Electrostatic Precipitator (ESP) is an environmentally friendly equipment primarily used for removing and recovering dust and tar mist from flue gas, thereby purifying the gas. It is widely applied in gas purification and treatment in industries such as carbon production, lime kilns, metallurgy, fertilizer production, coking, gas generators, waterproof coating asphalt smoke, and granulation processes.

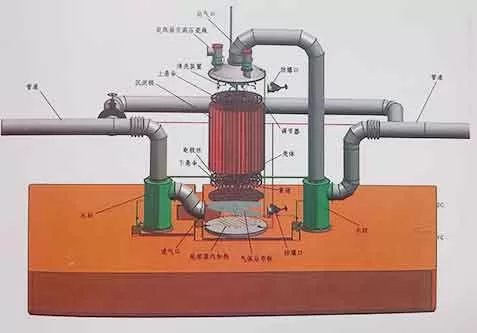

The ESP consists of a main body and electrical components. During operation, high-voltage DC current generated by a high-voltage generator is introduced into the ESP body via high-voltage cables and insulators. Inside the equipment, the collecting electrode acts as the positive pole, and the corona wire acts as the negative pole, forming a high-voltage electric field between them. Tar-containing gas undergoes ionization in the high-voltage electric field. Charged tar particles then move towards the collecting electrode, and upon reaching it, they flow downwards along its surface into the bottom of the equipment, eventually being discharged through the designed drain outlet at the bottom.

Working Principle

The dust removal process of an electrostatic precipitator can be divided into the following stages:

- Ionization of dust-laden gas.

- Charging of dust and tar particles.

- Movement of charged particles towards the oppositely charged electrode.

- Discharge and collection of charged particles.

- Flowing down the electrode under gravity.

One of the key factors affecting dust removal efficiency is the migration velocity (W) of charged dust particles; higher values lead to higher efficiency. To increase the migration velocity, it is necessary to increase the operating voltage or decrease the corona onset voltage to increase the corona current, thereby increasing the charge adsorbed on the dust particles. Given a constant migration velocity, improving dust removal effectiveness also requires increasing the area of the collecting electrode (A). Our company's FW electrostatic precipitators feature large collecting electrode areas and high migration velocities, ensuring high dust removal efficiency within the design range.