Pulse Bag Filter System

Advanced high-efficiency pulse bag dust collector with improved structure and pulse valve technology for superior dust collection performance

Key Features

Product Description

The Pulse Bag Filter is an improved new type of high-efficiency pulse bag dust collector based on traditional bag filter technology. This advanced system retains all the advantages of high purification efficiency, large gas processing capacity, stable performance, convenient operation, long filter bag life, and minimal maintenance workload, while incorporating structural improvements and pulse valve enhancements that solve the problems of outdoor installation and low compressed air source pressure.

The system employs compartment offline pulse jet cleaning technology, which overcomes the shortcomings of conventional pulse dust collectors and compartment reverse air dust collectors. It features strong cleaning capability, high dust removal efficiency, low emission concentration, small air leakage rate, low energy consumption, reduced steel consumption, compact footprint, stable and reliable operation, and excellent economic benefits.

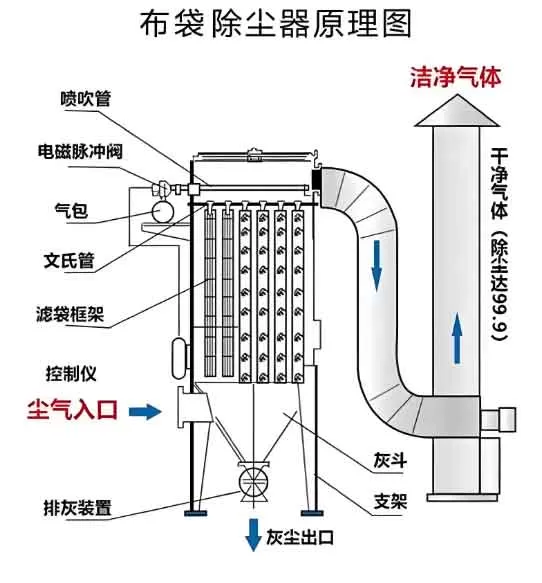

Working Principle

The Pulse Bag Filter consists of ash hopper, upper box, middle box, and lower box sections, with the upper, middle, and lower boxes featuring compartment structures. During operation, dust-laden gas enters through the inlet duct into the ash hopper, where coarse dust particles fall directly to the bottom of the ash hopper. Fine dust particles follow the airflow upward into the middle and lower boxes, accumulating on the outer surface of the filter bags. The filtered gas enters the upper box through the clean gas collection manifold and exhaust duct, then is discharged to the atmosphere via the exhaust fan.

The cleaning process begins by cutting off the clean gas outlet duct of the compartment, placing the filter bags in a state without airflow (compartment offline cleaning). Then, the pulse valve is opened to perform pulse jet cleaning with compressed air. The cutoff valve remains closed for sufficient time to ensure that dust separated from the filter bags after blowing settles into the ash hopper, preventing dust from reattaching to adjacent filter bag surfaces after leaving the filter bag surface. This ensures thorough filter bag cleaning, with programmable controllers providing fully automatic control of exhaust valves, pulse valves, and ash discharge valves.

Advantages

Applications

Technical Specifications

Performance Parameters

Structure & Materials

Filter Bag Selection Guide

| Operating Condition | Recommended Filter Material |

|---|---|

| Normal temperature, general dust | Polyester needle felt |

| High temperature (150-200°C), acid/alkali resistance | PPS (Ryton) needle felt |

| High temperature (200-260°C), acid/alkali resistance | P84 (Polyimide) needle felt |

| Corrosive gas, high temperature (up to 260°C) | PTFE (Teflon) needle felt |

| High temperature (up to 280°C), acid/alkali resistance | Fiberglass needle felt |