Acid Mist Packed Scrubber

Efficient acid mist packed scrubber for removing harmful acid gases and odors, featuring high purification efficiency, low resistance, and compact design.

Key Features

Product Overview

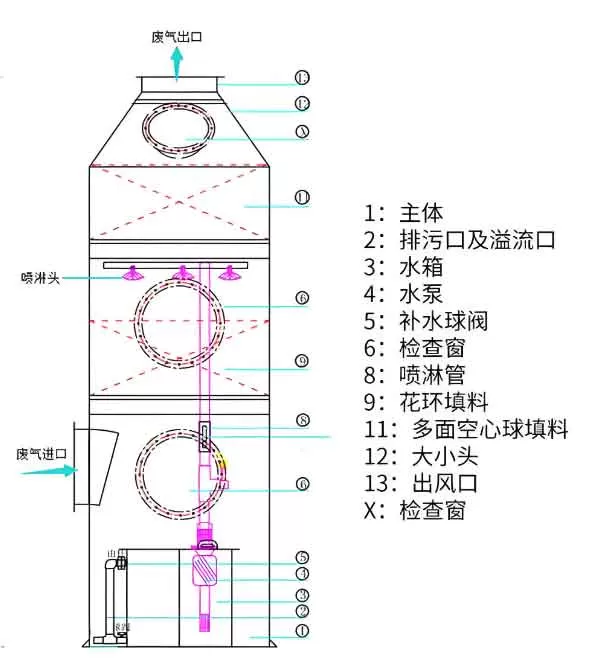

The Acid Mist Purification Tower, also known as acid gas purification tower, acid mist absorption tower, waste gas purification tower, and FRP acid mist purification tower, is a specialized equipment used to remove harmful gases from exhaust. It features a wide range of applications, high purification efficiency, low equipment resistance, and a small footprint, making it a commonly used and efficient purification equipment in waste gas treatment projects.

Working Principle

Sulfuric acid mist primarily consists of H₂SO₄ aerosols, which have small particle sizes (typically 0.1-10μm) and high dispersion, making them difficult to capture effectively by traditional filtration methods. The acid mist purification tower achieves purification through a combined process of "spray neutralization + packing interception." The specific process is as follows:

Waste gas containing sulfuric acid mist enters from the bottom of the tower body and flows upwards under the action of an induced draft fan. The spray system at the top of the tower atomizes an alkaline absorption liquid (commonly 10% sodium hydroxide solution or 8% sodium carbonate solution) and sprays it downwards, creating a counter-current gas-liquid contact environment. The sulfuric acid mist reacts with the absorption liquid to neutralize: H₂SO₄ + 2NaOH = Na₂SO₄ + 2H₂O (or H₂SO₄ + Na₂CO₃ = Na₂SO₄ + H₂O + CO₂↑), forming soluble sodium sulfate, thus converting gaseous pollutants into liquid substances. The acid-resistant packing inside the tower (such as PP Pall rings, multi-faceted hollow balls) further enhances the purification effect. The liquid film formed on the surface of the packing increases the gas-liquid contact area, and tiny sulfuric acid mist particles not directly neutralized are adsorbed by the liquid film, condense, and flow into the circulating water tank at the bottom of the tower with the liquid. The purified gas passes through the demisting layer at the top of the tower (usually a baffle or mesh) to remove entrained liquid droplets, finally meeting emission standards.

Advantages

Applications

Technical Specifications (PH Controller)

| Parameter | Value |

|---|---|

| pH Value Measurement Range | 0~14.00PH, 0.01PH |

| ORP Value Measurement Range | -1999~+1999mV, 1mV |

| Temperature Measurement Range | 0~100℃, 0.1℃ |

| Input Impedance | ≥10¹²Ω |

| Stability | ≤0.02PH/24h |

| Repeatability | ≤0.01PH |

| Temperature Compensation | Automatic (0~100℃) / Manual |

| Output Signal | 4~20mA (isolated output), max load 750Ω |

| Control Output | 2-way relay output, 220VAC/3A, normally open contact |

| Communication Interface | RS485 (optional) |

| Power Supply | AC220V±10%, 50Hz |

| Protection Level | IP65 |

| Working Environment | Temperature: 0~60℃, Humidity: ≤85%RH |

| Dimensions | 146×146×150mm (H×W×D) |

| Opening Size | 138×138mm |

Installation and Usage Instructions

The acid mist purification tower is typically installed vertically. The inlet and outlet pipes should be connected securely to prevent leakage. Ensure proper drainage for the circulating liquid. Regular maintenance, including checking the spray system and packing, is crucial for optimal performance. The PH controller should be calibrated periodically to ensure accurate monitoring and control of the absorption liquid.