RCO Regenerative Catalytic Oxidizer

Integrated system utilizing activated carbon adsorption and catalytic combustion for efficient treatment of organic waste gases.

Key Features

Product Description

The Activated Carbon Adsorption + Catalytic Combustion Purification Device is an advanced waste gas treatment equipment that ingeniously combines the strong adsorption capacity of activated carbon with the oxidative decomposition technology of catalytic combustion. This system first uses activated carbon to efficiently adsorb pollutants from organic waste gas. When the activated carbon reaches saturation, it is desorbed and regenerated using heat provided by the catalytic furnace. The desorbed high-concentration organic compounds then enter the catalytic furnace, where, under the action of catalysts (such as Pt, Fe-Cr, Cu-Cr, etc.), they are oxidized and decomposed into harmless carbon dioxide and water at low temperatures (200-500°C), finally achieving emission standards.

This device not only effectively purifies organic waste gas but also further saves energy through waste heat recovery, reducing energy consumption by up to one-third compared to traditional high-temperature combustion methods. Its design fully considers safety and operational efficiency, and it is widely used in various industries such as petrochemical, pharmaceutical, iron printing/color plate coating, and automotive painting, providing enterprises with economical and efficient environmental protection solutions.

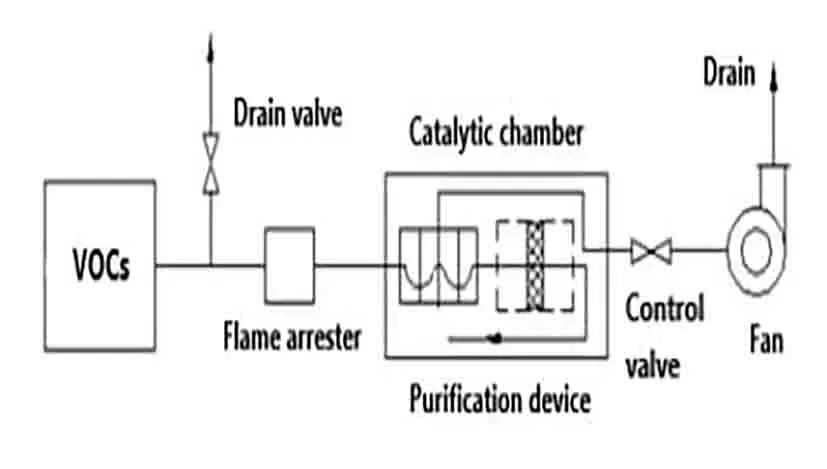

Working Principle & Process Flow

Adsorption System

For high-volume, low-concentration organic waste gas, a pre-filter is first used to remove dust and large particulate matter. Subsequently, the waste gas enters the activated carbon adsorption unit. The adsorption boxes can be arranged in parallel, allowing one carbon box to undergo online desorption while the others continue adsorption, achieving a continuous operation mode. The entire adsorption process is automatically controlled by a PLC, precisely setting adsorption and desorption times.

Desorption System & Catalytic Combustion

The desorption unit uses a catalytic oxidation furnace. The electric heating device is activated to bring the internal circulating hot air source to the boiling point of the organic compounds, promoting their desorption from the activated carbon and entry into the catalytic chamber for catalytic decomposition. Under the action of a catalyst, organic compounds are converted into harmless CO₂ and H₂O at lower temperatures (200-300°C), releasing heat. The reaction equation is:

CₙHₘ + (n + m/4)O₂ —(200-300℃, Catalyst)→ nCO₂ + m/2H₂O + Heat

The energy released by catalytic combustion can be used for subsequent activated carbon desorption, achieving energy recycling. Once the auto-ignition temperature is reached, the electric heating device can stop working or only one set can be used for compensatory heating, thereby saving energy. The desorbed organic solvent gas passes through a dust filter and flame arrestor, then a heat exchanger, and finally enters the heating chamber for temperature increase before decomposition in the catalytic bed. The tail gas exchanges heat with low-temperature gas through a heat exchanger, further improving system energy efficiency and ensuring waste gas meets emission standards.

Components Introduction

Electric Heater

The electric heating tube consists of a φ16 high-temperature stainless steel thin tube, an inner lining of high-temperature magnesium oxide, and electric heating wires. It features high efficiency, rapid heat dissipation, and long lifespan, manufactured and inspected strictly according to national standards. Performance parameters:

- Electric power per heating tube: 2kw

- Cold insulation resistance: ≥200MΩ

- Hot insulation resistance: ≥5MΩ

- Power deviation: ±10%

- Aging time: 3000 hours

- Tensile strength: ≥998N

Catalyst

Utilizes high-quality domestic catalysts, such as TFJF type catalyst, with cordierite honeycomb ceramic as the carrier, γ-Al₂O₃ as the secondary carrier, and noble metals like Pd, Pt as the main active components. It features high activity, high purification efficiency, high-temperature resistance, and long service life.

| Ignition Temperature (Purification Efficiency ≥92%) | Toluene 4g/m³: 220℃, Benzene 4g/m³: 240℃, Xylene 4g/m³: 220℃, Ethyl Acetate 4g/m³: 300℃, Methyl Ethyl Ketone 4g/m³: 220℃, Cyclohexanone 4g/m³: 220℃, n-Hexanol 4g/m³: 180℃, Propanol 4g/m³: 280℃ |

| Dimensions | 100×100×50mm |

| Cell Density | 25.4 cells/cm² (φ1.3mm), Wall thickness 0.5mm |

| Specific Surface Area | Deep main crystal phase γ-A12O3: 43 m²/g |

| Bulk Density | 0.8 g/cm² |

| Space Velocity | 1.5×10⁴ h⁻¹ |

| Catalyst Active Temperature | 210℃ |

| Impact Resistance Temperature | 750℃ |

| Service Life | ≥10000 hours |

Safety Explosion Relief Device

Utilizes a diaphragm pressure relief method, which can promptly rupture to relieve pressure during abnormal equipment operation, preventing accidents. This project uses a flat slotted rupture disc (PF type), composed of a flat rupture disc and a sealing membrane, etc. The rupture pressure is controlled by a weakened structure formed by slots and holes. When the system is overpressured, the rupture disc stretches and breaks along the weak points, releasing pressure and protecting system safety. The rupture disc uses Shanghai Langyan brand, stainless steel material.

Activated Carbon

Honeycomb activated carbon is made from coal-based activated carbon, pressed into shape with molds and activated at high temperatures. It features a regular pore structure and high specific surface area, suitable for large air volume, low concentration waste gas treatment. It can adsorb acid and alkaline pollutants such as nitrogen oxides, benzene, formaldehyde, acetone, ethanol, ether, methanol, acetic acid, ethyl acetate, styrene, phosgene, and malodorous gases. Water-resistant products have acid and alkali resistance and can be used as catalyst carriers for wastewater treatment.

During use, it needs to be combined with a dust removal device and temperature and humidity controlled to extend its lifespan. Avoid excessively high temperatures (reduces adsorption capacity) and high dust content and oil mist (blocks micropores, increases resistance).

| Parameter | Specification |

|---|---|

| Main Component | Activated Carbon |

| Common Specifications | 100*100*100mm |

| Pore Density | 100 pores/square inch, 150 pores/square inch |

| Specific Surface Area | Greater than 700 m²/g |

| Normal Compressive Strength | Greater than 0.8MPa |

| Operating Temperature | Less than 400°C |

| Empty Tower Air Velocity | 0.8~1.0 m/s |

| Appearance | Product surface is flat, no cracks |

Advantages

Applications

Technical Specifications

| Parameter | Description |

|---|---|

| Treatment Air Volume | 1,000 - 50,000 m³/h (can be customized) |

| VOCs Concentration Range | 100 - 2,000 mg/m³ (inlet) |

| Purification Efficiency | ≥95% |

| Catalytic Operating Temperature | 200 - 500°C |

| Desorption Temperature | 100 - 150°C |

| Pressure Drop | Activated Carbon: < 1000 Pa, Overall System: < 2500 Pa |

| Adsorbent Material | Honeycomb Activated Carbon |

| Catalyst Material | Noble metal catalyst (Pt, Pd) or metal oxide catalyst |

| Control System | PLC automatic control, HMI interface |

| Energy Consumption | 30-50% lower than traditional thermal oxidation |

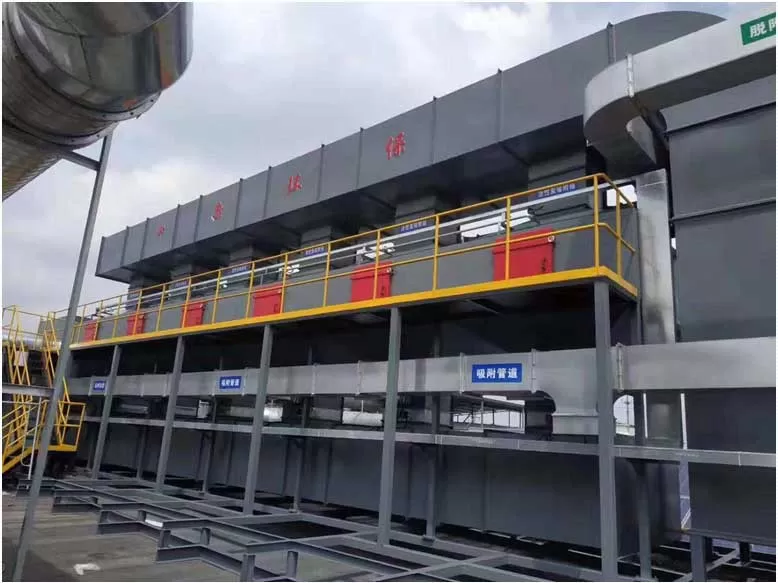

Case Studies

Pharmaceutical Manufacturing

VOCs treatment for pharmaceutical production processes.

Successfully implemented in a major pharmaceutical facility, achieving stable purification efficiency and significant energy savings through heat recovery.

Automotive Coating

Exhaust gas purification for automotive paint shops.

Provided a comprehensive solution for multiple automotive manufacturers, effectively treating paint fumes and ensuring compliance with strict emission standards.

Petrochemical Industry

VOCs control for petrochemical processing facilities.

Deployed in large-scale petrochemical plants, significantly reducing VOCs emissions and improving environmental compliance while maintaining cost-effectiveness.