Zeolite Rotor Concentration + Desorption (CO/RTO)

Efficient VOCs treatment for large air volume, low concentration waste gas, combining zeolite rotor concentration with catalytic oxidation (CO) or regenerative thermal oxidation (RTO).

Key Features

Product Description

The Zeolite Rotor Concentration + Desorption system is a globally recognized leading technology for exhaust gas concentration, especially suitable for treating large air volume, low concentration organic waste gas. It effectively removes VOCs through a continuous process of adsorption, desorption, and concentrated incineration. Zeolite, an aluminosilicate mineral with a unique cage-like structure, exhibits excellent adsorption, ion exchange, catalytic, acid, and heat resistance properties. Its special microporous structure allows selective adsorption of different molecules.

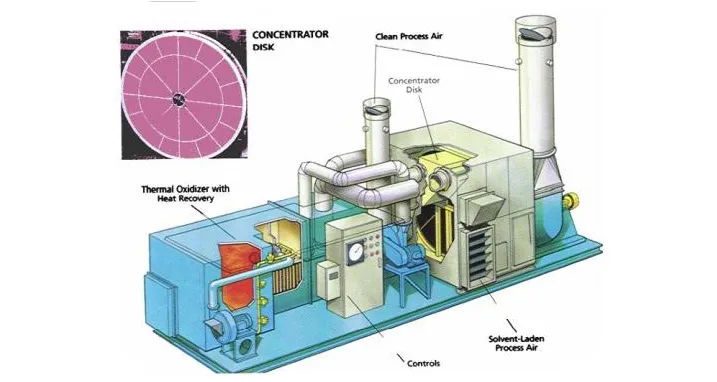

The system utilizes the adsorption characteristics of zeolite by loading it onto a rotor, enabling cyclic use of the adsorbent and concentration of target components. After concentration, the high-concentration organic compounds are desorbed using a desorption unit, which then introduces them to a heat source desorption device. Common desorption devices include Catalytic Oxidizers (CO) and Regenerative Thermal Oxidizers (RTO), which further purify the concentrated VOCs.

Working Principle

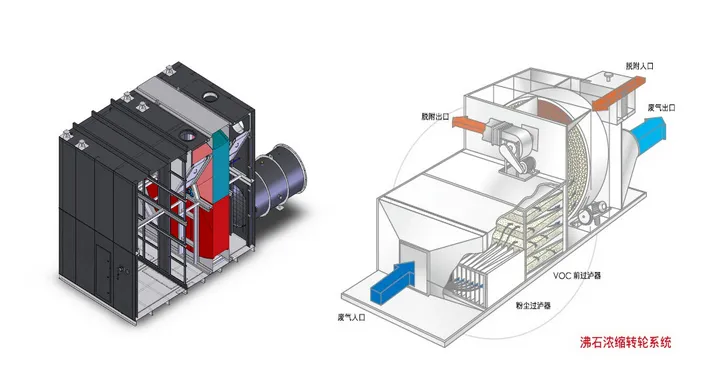

Zeolite Rotor Adsorption & Desorption Process

When VOCs-containing waste gas enters the zeolite rotor, the zeolite efficiently adsorbs most of the VOCs, significantly reducing the VOCs content in the treated gas, which is then directly discharged into the atmosphere after meeting emission standards. Subsequently, the zeolite rotor, after the adsorption process, undergoes high-temperature desorption to release the adsorbed VOCs, forming high-concentration VOCs gas. This process not only purifies the waste gas but also reduces the cost of subsequent treatment steps.

The zeolite rotor concentration zone consists of a treatment zone, a regeneration zone, and a cooling zone, which are fully utilized through the continuous operation of the concentration rotor. After passing through a pre-filter, VOC organic waste gas enters the treatment zone of the concentration rotor, where VOCs are efficiently adsorbed and removed, and the purified air is discharged from the treatment zone directly into the atmosphere. Subsequently, the zeolite rotor, after the adsorption process, enters the regeneration zone, where high-temperature desorption releases the adsorbed VOCs, forming high-concentration VOCs gas. Finally, the cooling zone is used to cool the rotor, preparing it for the next round of adsorption.

In the regeneration zone of the zeolite rotor, adsorbed VOCs are effectively desorbed and concentrated by 5 to 20 times using hot air. The rotor then enters the cooling zone for cooling. The air passing through here is heated and then introduced into the regeneration zone as regeneration air, thereby achieving energy savings. Depending on the actual air volume and VOCs composition, drum or disc type rotors can be selected for treatment.

Desorption Devices: Catalytic Oxidizer (CO) & Regenerative Thermal Oxidizer (RTO)

Catalytic Oxidizer (CO)

The Catalytic Oxidizer is an industrial equipment that treats organic waste gas at low temperatures using catalysts (e.g., Pt, Fe-Cr, Cu-Cr). It oxidizes harmful substances into harmless materials at 200-500°C, saving up to one-third energy compared to traditional high-temperature combustion and allowing waste heat recovery. The device includes an exhaust gas pipeline, catalytic unit, and heat source. Operating temperature is 220-350°C. With plate or tube heat exchangers, heat recovery efficiency reaches 70% and 40-50% respectively. The catalyst bed reaction temperature does not exceed 600°C, and catalyst life is 1-4 years.

The catalytic combustion device has a heating chamber (electric/gas heating). When the heating device is activated, and the hot air source reaches the boiling point of the organic compounds, VOCs are released from the zeolite and enter the catalytic chamber for catalytic decomposition into CO2 and H2O, releasing energy. This released energy is then used in the desorption area of the zeolite rotor, maintaining self-ignition of organic waste gas in the catalytic combustion chamber, allowing for continuous regeneration of the zeolite and catalytic decomposition of organic matter.

Reaction: CnHm + (n + m/4)O2 --(200-300°C, catalyst)--> nCO2 + m/2 H2O + Heat

Regenerative Thermal Oxidizer (RTO)

The RTO is designed for medium to high concentration organic waste gas treatment. It thermally oxidizes VOCs into CO2 and H2O at high temperatures (above 760°C), purifying the waste gas and recovering the released heat. Three-chamber RTO achieves over 99% decomposition efficiency and over 95% heat recovery, offering low operating costs and the ability to process large volumes of medium to low concentration waste gas. If the concentration is slightly higher, secondary waste heat recovery can further reduce operating costs.

The principle involves heating organic waste gas to above 760°C, causing VOCs to oxidize and decompose. The high-temperature gas flows through ceramic heat storage media, which heats up and stores heat, used to preheat subsequent incoming waste gas, saving fuel. The ceramic heat storage media should be divided into two or more chambers, each undergoing heat storage, heat release, and purge cycles. Under suitable waste gas concentration, the system can achieve self-sustaining operation without auxiliary fuel.

Advantages

Applications

Technical Specifications

| Parameter | Description |

|---|---|

| Treatment Air Volume | 5,000 - 100,000 m³/h (can be customized) |

| VOCs Concentration Range | 50 - 1,000 mg/m³ (inlet) |

| Concentration Ratio | 5 - 20 times |

| VOCs Removal Efficiency | CO: ≥95%, RTO: ≥99% |

| Desorption Temperature | 180 - 220°C |

| CO Operating Temperature | 220 - 350°C |

| RTO Operating Temperature | 760 - 850°C |

| Pressure Drop | Zeolite Rotor: < 500 Pa, Overall System: < 2000 Pa |

| Adsorbent Material | Hydrophobic Zeolite |

| Catalyst Material (for CO) | Noble metal catalyst (Pt, Pd) or non-noble metal catalyst |

| Control System | PLC automatic control, HMI interface |

Case Studies

Electronics Manufacturing

VOCs treatment for semiconductor and display panel production lines.

Successfully implemented in a leading electronics factory, achieving stable and efficient VOCs removal from large air volume exhaust.

Automotive Coating

Exhaust gas purification for automotive paint shops.

Provided a comprehensive solution for a major automotive manufacturer, effectively treating paint fumes and ensuring compliance with strict emission standards.

Printing Industry

VOCs control for gravure printing and packaging processes.

Deployed in multiple printing facilities, significantly reducing VOCs emissions and improving air quality in the workplace.